AURUM® (TPI) Distribution in Europe: Mitsui Chemicals Appoints BIEGLO

Mitsui Chemicals Inc. appoints BIEGLO GmbH the distribution of AURUM ®, thermoplastic Polyimide powder (TPI) in Europe including Switzerland and the UK. Accessibility to this Ultra High Performance Polymer through BIEGLO will open new opportunities for this product that is positioned at the top of the polymer pyramid.

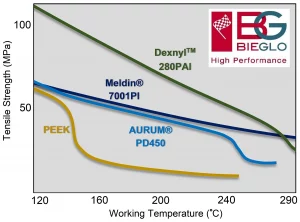

The advantages of AURUM ® are the extremely high glass transition temperature (Tg) of 245°C and its outstanding mechanical and chemical properties across a wide range of temperatures. Compounders and other converter that are able to melt-process polymers at elevated temperatures can use AURUM ® to produce parts with superior thermal and mechanical properties.

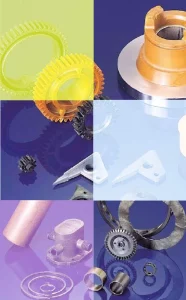

Typical applications are high-performance washers, ball-bearing cages, dry bearings, seals and gears - where excellent mechanical & tribological properties and temperature resistance are paramount. In addition, thermoplastic polyimide AURUM ® is usable for advanced coatings, and clean-room applications due to low trace amounts of outgasing and metallic impurities. Used in aviation, automotive and other industries, AURUM® can be compounded and converted like any other thermoplastic.

The growing demand for HPPs lead BIEGLO to focus on the high-temperature segment. Besides CoPEEK from Panjin Zhongrun, BIEGLO also markets PI-shapes (rods and sheets) of the Meldin® 7000-Series from Saint-Gobain and Polyamide-imide (PAI). BIEGLO owns specialized web-shops www.PEEK-shop.de and www.POLYIMDE-shop.de to offer standard HPP-products.

Mitsui Chemicals is based in Tokyo and looks back on a long history in the chemical market. They offer a diverse portfolio of specialty products, such as chemicals and intermediates, specialty polymers and engineering plastics.

Both companies look forward to a successful co-operation, to market AURUM ® in Europe